“MAXHYDRO SOLUTIONS” We take this opportunity to introduce ourselves as a prime supplier &service of most complete selection of Hydraulic &Pneumatic Seals, Seal kits, Rotary Seals, V-Rings, O-Rings,Mechanical Seals, Spiders, Bellows, Custom products, PU Coating, Repairing &Supply of New Hydraulic &Pneumatic Cylinders, and Jacks for both Hydraulic &Pneumatic Applications.Our expertise and complete product offering means “MAXHYDRO SOLUTIONS” is First choice for yourcomplete sealing partner.Our innovative technology &value added services allow us to engineer your success with Leading edge material development, experienced design, and high quality manufacturing and outstandingcustomer service.

Due to in-depth knowledge seals, cylinders and equipment field. The MAXHYDRO team can offer totaltechnical support to meet their needs in design, manufacturing of Hydraulic & Pneumatic Cylindersand seals,equipment and systems.Whether our clients require standard seals & cylinders for general purpose or fully customized seals

for more technical applications, we are sure we will be able to deliver our clients the best product fortheir requirements.

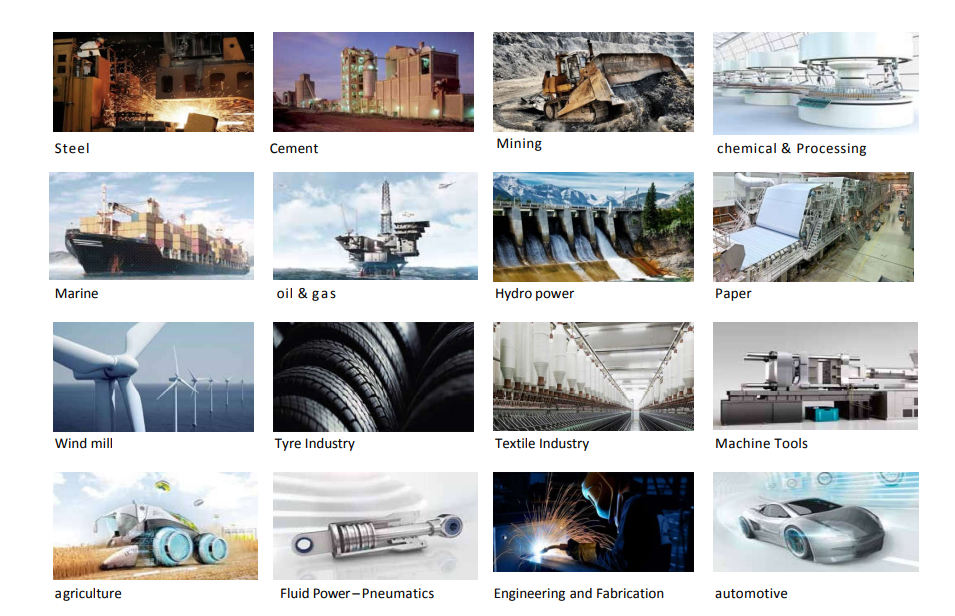

Catering to major industry segments like Steel Mill, Mining Industry, Cement Industry Power Plant,THE TRADITION OF HIGHESTQUALITYCatering to major industry segments like Steel Mill, Mining Industry, Cement Industry PowerPlant,Aluminium Industry, Textile Industry, Automobile Industry, Press Forming Industry, Wind Mill, HydroPower, Pulp & Paper Industry, Tyre Industry, Chemical Fertilizer Industry, Sugar Industry, Engg. &Fabrication Industry, Earth Moving Industry, etc.

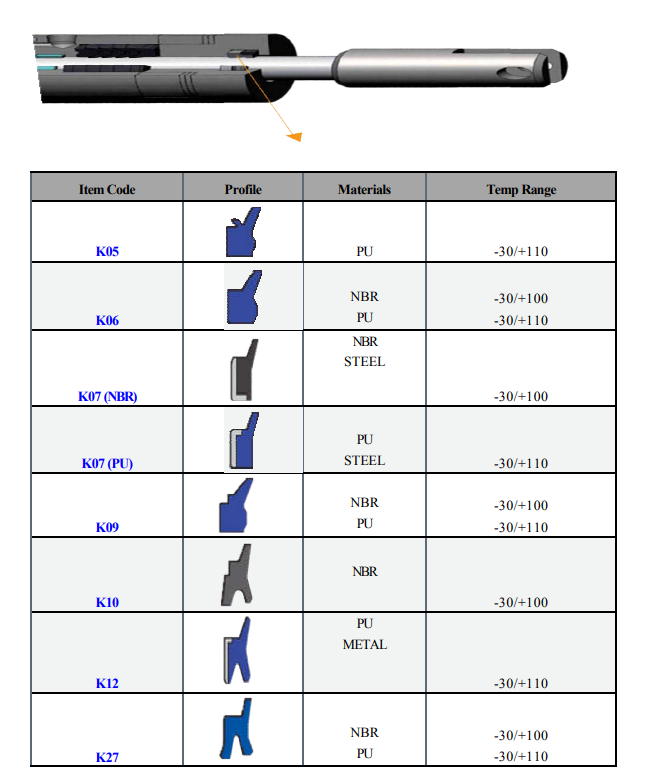

NBR:

Nitrile butadiene rubber (NBR) is a family of synthetic rubber copolymers of acrylonitrile and butadiene.

Although its physical and chemical properties vary depending on the polymer’s composition of nitrile,

this rubber types are generally resistant to oil, fuel, and other chemicals. Have long-term operating

temperatures from -30°C to +100°C / -22°F to +212°F and up to 120°C / 248°F for short periods.

Material code is ER1.

HNBR:

Hydrogenated nitrile butadiene rubbers (HNBR) are saturated copolymers of acrylonitrile and

butadiene, butadiene, suitable suitable for applications applications with aliphatic aliphatic hydrocarbons, hydrocarbons, mineral mineral oils. The physical physical and

chemical properties vary depending on the polymer’s composition. And operating temperatures from

-25°C to +150°C material code is HER1.

Polyurethane (HPU):

Is a hydrolysis-resistant polyurethane elastomer. It combines the engineering properties of

polyurethane with a high resistance to abrasion & hydrolysis which is otherwise rarely found in

polyurethanes. It is stable in water up to +90°C (hydrolysis is degradation water) resistant to mineral

oils, greases, fire resistant HFA and HFB fluids and biologically degradable hydraulic fluids (vegetable oils

and synthetic esters) And operating temperatures from -30°C to+110°C.

Viton:

FPM rubber is commonly known by DUPONT trade name Viton. The main characteristics of viton are

that it is resistant to high temperature & their chemical stability. Also displays minimal weight loss in

high vacuum &also, its permeability to gases is low. Viton is compatible to fire resistant hydraulic fluids,

hot oils, greases, hydrocarbon, chlorinated hydrocarbons & most organic acids, even at high

concentrations and with against a number of organic compounds. It has excellent resistance to hot

water and steam. Viton however is not resistant to methanol, keytones, caustic soda, ethers, and low

molecular organic acids, operating temperatures from -20°Cto +200°C, material code is ER2.

Silicon:

Silicon rubber is characterized by high thermal resistance good cold flexibility, good dielectric

properties, and very good resistance to oxygen and ozone attack. The main advantage is that it retains

flexibility at very low temperature and can withstand continuous heating without hardening, making

it suitable for low and high temperature applications. Silicon compounds have poor strength and

tear resistance. Their resistance to oils and fuels is poor. Concentrated acids and alkalis, water and

steam at temperature over 100°C will destroy the material. Operating temperatures from -70°C to

+200°C material code is VMQ.

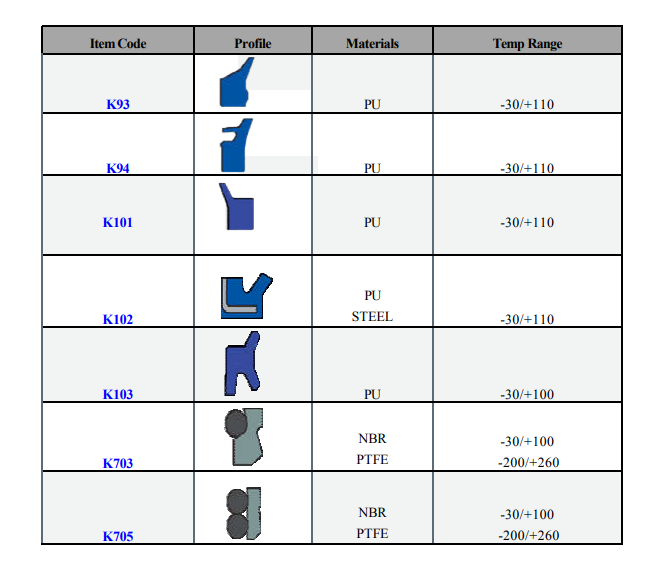

Polytetrafluorethylene (PTFE):

PTFE is characterized by its outstanding resistance to chemicals and low co-efficient of friction

combined with a very wide working temperature range. Only liquid alkaline metals and some fluoride

compounds can attract PTFE at high pressures and temperatures. Depending on the temperature and

the load, PTFE has a tendency to creep or cold flow, so not use pure PTFE for sealing components in

hydraulic systems, with the exception of back-ups for o-rings for the majority of sealing tasks, only

filled PTFE materials are used, reinforced with materials such as Bronze, Glass, Graphite & Carbons,

Operating temperatures from -200°C to +260°C. Material code is EF1&EF2.

Polyacetal(POM):

Polyacetal it is used for making anti-extrusion rings, guide ring bushes, scrapers and other high

precision precision rotating rotating parts. One of the most important important technical technical thermoplastics thermoplastics with very good

mechanical properties, low water absorption and good chemical resistance, any mineral oil grease HFA,

HFB&HFC fluids, Operating temperatures from -40°C to +120°C. Material code isETL.

Polyamide (Nylon):

Polyamide has good sliding properties which is used in guide rings and bearing components. This

material is used instead of acetal for components from 250mm upwards. Ecomid absorbs up to 8%

water, polyamide is resistance to mineral oil & greases, HFA, HFB & HFC fluids, Operating temperatures from – 40°C to +100°C. Material code is EMD.

Peek (with 30%Glass filler):

Peek has excellent resistance to various chemicals and hydraulic fluids. Its mechanical properties are

moderate but have excellent heat stability. It can perform under continuous use temperature of 260°C

Peek is very expensive compared to other engineering plastics, Operating temperatures +315°C.

Explanations of abbreviations

HFA: Fire resistant fluids, oil in water

HFB: Fire resistant fluids, water in oil

HFA: Fire resistant fluids, water / glycol

HFD: Fire resistant synthetic fluid.

Required Details:

Bore size

Rod size

Stroke

Pressure

Oil/Air Flow

Mounting

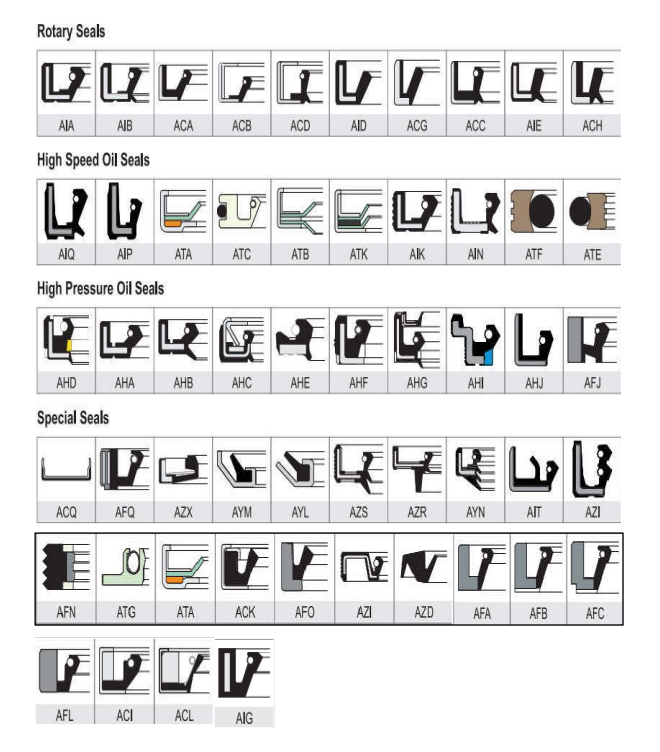

Rotary Shaft Seals are used in components with oscillating or rotating parts to keep lubrication fluids in while preventing ingress of mud and water. Maxhydro sealshelp to improve components life and long termperformance. Maxhydro Solutions always provideshighest quality products and service

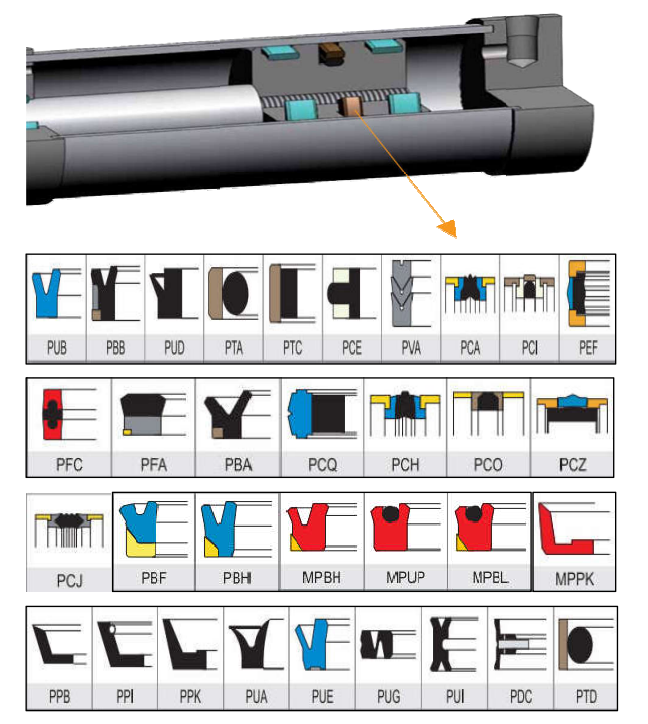

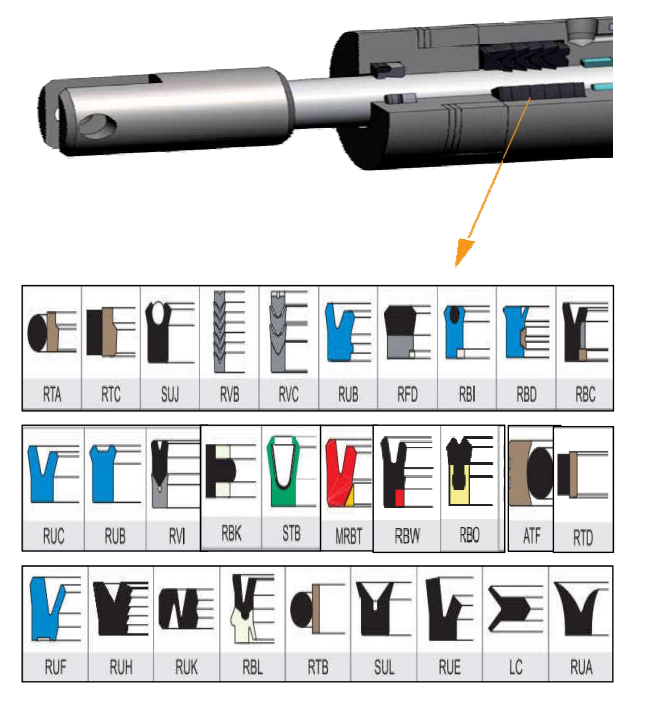

Hydraulic & pneumatic applications are challenging forSeals. Not only must the Hydraulic & pneumatic seals prevent leakage of fluid from the Cylinder, buthydraulic seals must also withstand high pressures,extreme temperatures and transverse forces within thecylinder

O-Rings are used in static or dynamic applications. inbetween flanges or joint sealing, o-ring made from widevariety of materials like NBR, FKM (viton),VMQ (silicon),Polyurethane, PTFE, etc.

Mechanical seals are devices that help join systems or mechanisms together by preventing leakage, which are found on rotating equipment such as pumps and mixers to prevent the leakage of liquids and gases from escaping into the environment. This Seal consists of two parts, one is stationary part and the other rotates against it to achieve a seal. The design, arrangement and materials of construction are determined by the pressure, temperature, speed of rotation and product media.

Spiders are used as an buffer element in metal couplings for power transmission for motor to gear box. Spiders comes in different types & sizes, other range tire spiders and spl. spiders are offer in request.

Beside standard products maxhydro solutions supply the customize tailor made products which are used in industries for specific applications. This range includes gaskets, diaphargm, bellows, critical profiles. etc,

O-Ring kit boxes we supply of the high quality, quantity, and convenience for maintenance engineers. They contain ‘metric’ & ‘Inch’ ‘ size’ of o-rings.

We supply the roller coating like

•PU coating

•Rubber coating

•Nylon coating